Furnaces are sophisticated devices, and understanding the components’ fundamental aspects is very helpful when addressing many furnace problems. Even if most of these problems require professional repair or fixing, you can at least make the general idea about what’s wrong with your furnace.

Modern furnaces come with several features for accurate and proper operation features, which is both a good and a bad thing. The good thing is that your furnace will run accurately for a long time without developing problems. On the other hand, some of these features are complicated and tricky to fix, so professional help is almost always needed. One of the features that provide safe operation for your furnace is the pressure switch. And you cannot address any problems with the furnace pressure switch unless you understand its role, what causes malfunctioning, and how you may test/replace the pressure switch on your Ducane furnace.

Page Table of Contents

What’s the primary purpose of the furnace pressure switch?

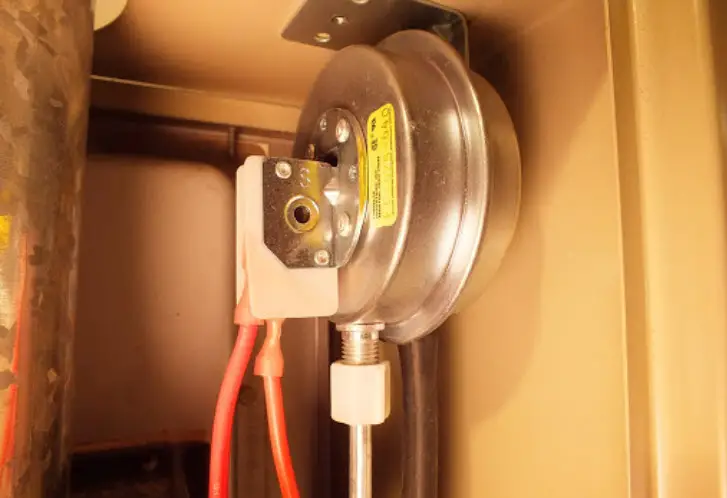

The pressure switch is a built-in feature that has to supervise the inducer motor’s negative pressure. When you modify the thermostat, you will also send a request to the control board. The control board will also monitor the centrifugal switch to ensure that it’s not energized and open.

The pressure switch will diagnose the draft motor and start push heat throughout your house. When the blower motor’s pressure level is wrong, the button will turn off the furnace ignition.

All in all, the pressure switch will protect against harmful gas leaks and reduce the risk of furnace cycling in case of a mechanical problem. It will improve the safety of your household and reduce the risk of further damage to your furnace.

The model of furnace you have will count for the type of pressure switch you have. Single-stage, conventional furnaces come with one hose that goes to the draft inducer’s body, whereas condensing models come with two hoses that go to the pressure switch. One hose will identify the pressure at the draft inducer, whereas the other hose works as a venting-pressure sensor. Two and three-stage furnaces may present even three hoses for improved accuracy.

What are the causes of pressure switch problems?

Sometimes, the pressure switch will be stuck open, and recycling the furnace will solve the problem. You will have to remove the wire connections from the pressure switch. Once the thermostat sends a request for heat, the draft fan should start running. As the fun is operating, you should short the pressure switch wires (use a jumper to connect them manually). Should your system run, your furnace does have a pressure issue, but it’s not the pressure switch causing it.

Blocked exhaust or air intake

The furnace has to use fresh air for combustion, and the combustion gases have to be eliminated/vented. When the exhaust or the intake is blocked, the inducer fan doesn’t create negative pressure so that the pressure switch will stay open. But being stuck open isn’t an issue; it’s keeping you safe.

Bird nests, snow, ice, leaves, and wasp nests are most commonly caused for blocked exhaust.

You will have to take a look at the flue. If your furnace is 80% AFUE rated, the vent is probably on the roof. If your furnace is high-efficiency (over 90% AFUE rate), the vent could be outside the house’s an outside wall.

Always ensure that the air intake is clear and clean. Don’t forget to check the air vents of the cabinet, cleaning them if necessary.

You may clean yourself the air intake, and professional cleaning will cost you anything from $80 to $150.

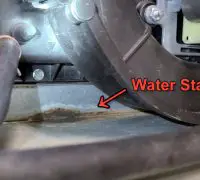

Blocked condensate drain

High-efficiency furnaces come with a condensate drain, which can become blocked at some point. Condensation backup will go into the blower fan housing, so the furnace pressure and the pressure switch will develop issues.

You will need particular products and equipment for troubleshooting blocked drain line. A shop vacuum could be necessary, so you may spend $100 if you clean it yourself. Should you hire the professionals, you may spend almost $300 on cleaning.

Failure of the draft inducer motor

The draft inducer motor is a blower that generates a flow of combustion air through the heat exchanger so that the combustion exhaust byproducts are eliminated outside your house through the flue vent. When it’s not properly functioning, the pressure switch will malfunction as well.

Leaks around the system

First of all, you need to make sure that the furnace’s leaks come from the furnace and not other appliances close to it. Even if moisture and condensate are regular for high-efficiency furnaces, it becomes a problem when the water isn’t drained properly, causing leakage and affecting all components.

Electrical failure of the pressure switch

If wiring is loose, damaged in any way, the pressure switch could fail. You should make sure that the furnace gets power before troubleshooting.

Age of the furnace

As your furnace gets older, the components wear out too. Sometimes, it could be the old age of the furnace, causing the pressure switch problems. Pressure switches will malfunction because of age, so precise readings will occur, and the furnace will malfunction.

How can you check the pressure switch?

The diaphragm in the pressure switch is a typical cause of problems. In time, the diaphragm becomes stiff or coated, which reduces efficiency. Tears, holes, and various damage to the diaphragm will cause malfunctioning of the pressure switch. The buildup of dirt and dust can also affect the pressure switch’s performance, whereas tiny bits of contaminants may block the button and lead to shut down.

Figuring out the cause of the problem on your pressure switch is tricky, and replacing the affected unit is the most straightforward solution pretty often.

You don’t just go ahead and replace the pressure switch; you should check if it’s bad or not first. Here are the steps to take:

Shut down the power

You have to begin by turning the power off to your furnace. Switch off the disconnect button placed on or close to the furnace. If you don’t see it, you may turn off the furnace’s power in the service panel/breaker box of your house.

Examine the pressure switch hose

Continue with putting aside the primary access panel on the front of your furnace. Observe the hose/hoses attached to the pressure switch to ensure that everything is connected at both ends and there are no apparent damages. Replace the hose if it’s cracked.

If there’s more than one hose, you have to remove and reinstall all later on. You should ensure that the hoses aren’t obstructed inside. Never blow into the hose while it’s still attached, as you may break the pressure switch.

Verify the hose port

Use a good flashlight to check the hose port on the pressure switch, identifying any obstructions. Use a tiny screwdriver or a similar tool for removing debris. Be gentle as you don’t want to perforate the switch body. Again, don’t blow into the inlet to get rid of the obstruction. Put the hoses back in place.

Take a look at the furnace cover

You will need to examine the ventilation slots on the furnace cover and remove any debris. Should it be required, you will also have to clean the vents.

Check the vents

If you have a condensing/high-efficiency furnace, you will also have to check the vent pipe for any blockage. The vent pipe is made with white plastic (PVC) for the condensing models; it goes on the sidewall or through the roof of your house.

Test the switch for resistance

You will have to disconnect the wires attached to the pressure switch; you pull the switch terminals’ wire connectors. Use a multimeter to test the pressure switch for resistance (set it to ohms).

You will have to touch every tester probe to the switch terminals. The tester is supposed to read 0 or close to 0, showing resistance. When the reading is higher, the pressure switch is failed, and you will have to replace it.

Check the furnace operation

Continue with reconnecting the wires to the pressure switch. Put back the furnace’s access panel, and turn on the power to the furnace. Check to see if your furnace is running.