If you're looking to fix or replace your Heating or A/C system, we can connect you with a reliable and cost-effective professional in your area.

There are many reasons people choose to install Goodman furnaces in their homes, and the fact they come with control boards is one of them.

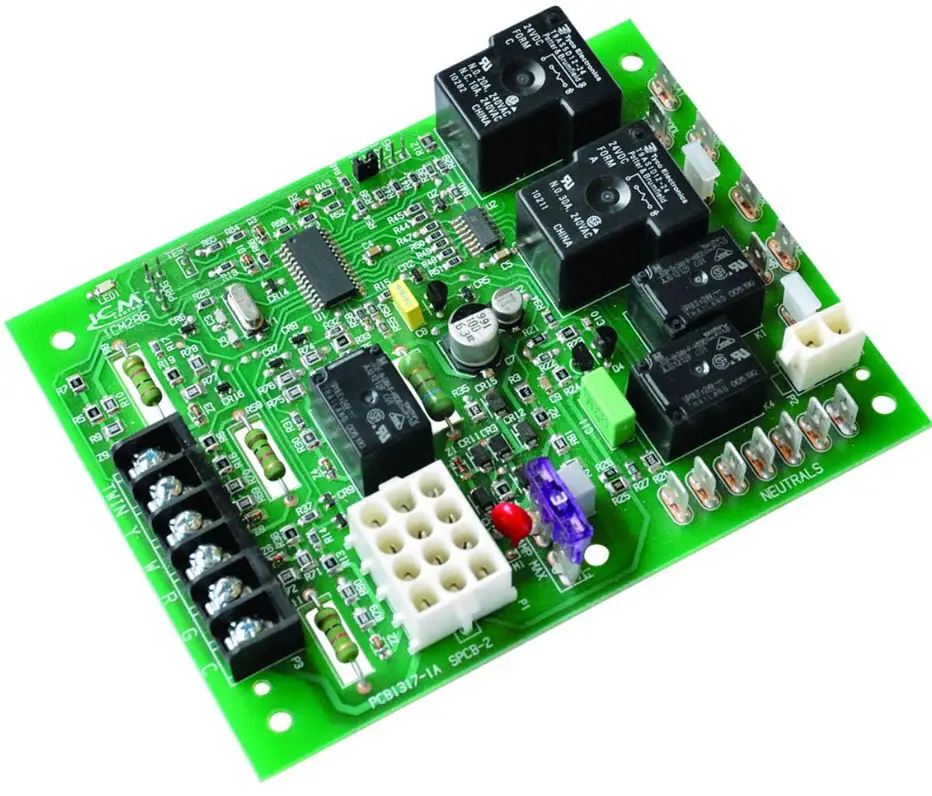

Circuit boards are not only controlling the ignitor, but they also come with warning lights with led indicators informing you of various problems on your furnace. Even your Goodman furnace is expected to work for many years; addressing any issues from the moment they occur will expand the durability and ensure proper performance. And one of the problems you cannot postpone is a faulty circuit board on your furnace.

Page Table of Contents

How do you know that your circuit board has gone bad and requires replacement?

As Goodman furnaces are a highly-effective yet complicated device, you should pay attention to the warning signs of a circuit board gone bad. There are two main types of control boards for the furnaces:

Ignition control boards

They’re utilized for controlling the ignitor, the valve, and the flame sensing circuits. Older units used to have this type of control board, and it’s not common nowadays.

Built-in furnace controls

In the integrated control boards, the built-in features are similar to older models, but they’re also capable of controlling the furnace blower.

No matter the type of control board, the component monitors several elements on the furnace as it performs several operations. When it starts to malfunction, some warning signs will be hard to miss:

Warning lights

Goodman furnaces come with led indicators that work as warning lights. Any red warning lights should worry you, and make a call of your technician.

Interruptions in the even phase

Any furnace control board will go through specific sequences of events. For example, turning on the induced draft motor is the first step, followed by the closing of the pressure switch. When you observe that the ignition doesn’t turn on, but the blower still runs after all the other elements have stopped, you will have to call in the professional for repairs.

The temperature is not stable.

If you observe that the indoor temperature fluctuates a lot, your house is getting too hot or too cold, and your furnace may have developed a problem. The situation is worrying if the thermostats don’t present any signs of failure or malfunctioning. Make sure to contact the technician to check the control board before it gets too cold outside.

Any of the signals above should worry you, especially if you’re suspecting that the furnace controls aren’t entirely operational. Unless you’re a professional working in the HVAC industry, you shouldn’t try to fix the control board independently. You may replace it (keep reading to find out how), but fixing isn’t straightforward for the regular customer.

How should you replace the circuit board on your furnace?

If you know for sure that the circuit board is the culprit for your furnace’s malfunctioning, it’s not expensive to get a replacement. You can find it according to your Goodman furnace model for $100, give or take.

Even if the circuit board isn’t expensive or very complicated, we should highlight that it’s still a dangerous operation. Only trained professionals should, in fact, mount or service the heating equipment. When you’re handling working equipment, it’s crucial to comprehend all the safety rules to follow on labels and tags that come with the kit. Not following all safety recommendations could severely damage your furnace, cause personal injuries, and be fatal.

Electrostatic discharge (esd) precautions

Always be careful when mounting or servicing your furnace for avoiding and controlling the electrostatic discharge. And may affect the electronic elements, and you must follow the recommendations for preventing ESD from personnel and hand tools.

What steps to take for protecting the controlESD?

Take every single step, and don’t miss any details when trying to replace the circuit board. Here’s how to do it safely:

- Begin with disconnecting all power to your furnace. It’s important not to touch the control or any of the wires before discharging your body’s electrostatic discharge to the ground.

- You will ground yourself, touching the hand and tools to the clean furnace surface, close to the control board.

- You may touch the chassis after servicing the furnace; your body becomes recharged with static electricity while you’re shuffling your feet and move. You will need to reground.

- It’s necessary to reground every time you touch items that aren’t grounded.

- You have to protect the control and reground before working with the new control. It’s safe to keep used and new controls in different recipients before you touch the ungrounded items.

- An ESD service kit can also be of use for reducing the risk of ESD damage.

How should you remove the current circuit board?

You will need to remove the old circuit board while following the next steps:

- Begin with turning the thermostat to the off position, setting it to the lowest setting

- Continue with turning off the electrical supply to your furnace. Should you skip this step, you could cause an explosion, fire, personal injury, and even death.

- Make sure that you label every wire with the proper terminal purpose.

- You have to disconnect the thermostat lead wires and the power supply from the ignition control.

- You also have to disconnect any low voltage/line, ground leads from the current ignition control, and accessory wire.

- End with removing any fasteners, screws, together with the old ignition board.

What’s the recommended method to mount steps the new circuit board?

No matter which model of circuit board you’re using, the steps for installation are similar:

- Begin with grounding yourself before mounting the new circuit board

- Use the same fasteners and screws that you’ve just removed for mounting the new board.

- Connect low voltage/lines, thermostat, ground wires, and accessory

- Make sure to test the sequence of operations.

Operation

As you apply power, the control will monitor the limit switch, rollout switch, gas valve output, pressure switch, and flame sense.

In case of request for heat, the control has to maintain the limit switch closed, but the pressure switch contact open before it turns on the inducer blower; the latter will be energized for 15-seconds throughout the pre-purge process. Before the pre-purge stage, the pressure switch contact gets closed, while power is applied to the heated surface ignitor.

When a flame is identified throughout the 7-second attempt for the ignition phase, the gas valve becomes energized, and the blower motor turns on after a 30-second delay.

When there is no longer a request for heat, the control turns off the gas valve, the inducer blower also turns off after the 15-second post-purge period, whereas the heat blower turns off after the jumper-selectable phase. In case the jumper is missing, a 120-seconds delay for the default heat blower off will occur.

In case of a call for cool, the control energizes the cool blower when the 5-second delay is over. Once the call for cool is over, the control needs 45-seconds delay for turning off the cool blower.

We can definitely connect you with a trusted provider in your area to repair, replace or maintain your heating and A/C systems. Why not let us find a professional for you?