The manufacturing industry makes up 30% of the global GDP, making it among the largest on the planet. Manufacturing companies make cars, appliances, electronics and dozens of other things that many of us use every day. A lot goes into manufacturing and there are many steps and processes that need to be taken care of.

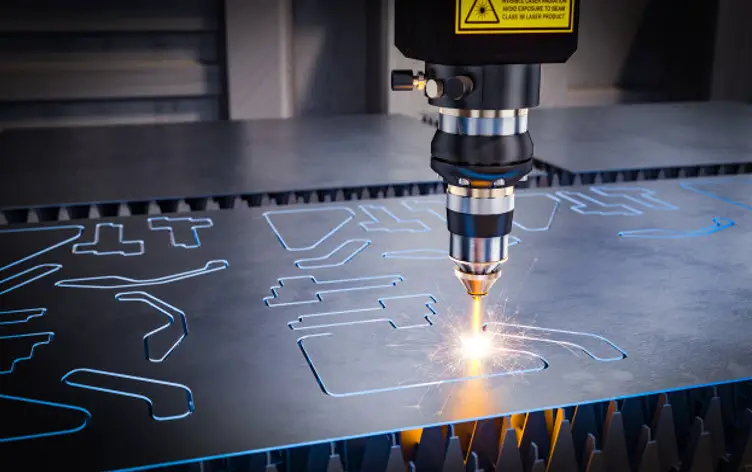

As a result, companies are looking for anything they can do to optimize their manufacturing. In many cases, a laser engraving machine is just what they need. Read on to learn more about some of the many benefits of a laser engraving machine for manufacturing.

Page Table of Contents

Can Help Personalize, Mark or Categorize Anything

When manufacturing products, there are a lot of materials and pieces involved. Even something as simple as a toaster has several parts that all need to seamlessly work together. Even one simple thing being out of place or the wrong size can prevent the product from working. Sometimes, these components are small and difficult to distinguish from one another.

This can make successfully manufacturing and building your product difficult. Laser engraving helps to ensure that all of the vital components you need are properly marked. Each part can be precisely marked with its name, it’s use or instructions to ensure everyone who sees it knows what it does. Doing this will eliminate all possibility of confusion and make sure everything can be put together correctly.

Laser Engraving is Environmentally Friendly

More than ever, companies are looking to be more environmentally friendly, including those in manufacturing. Using sustainable energy and materials, along with reducing energy usage, are of incredible importance. Thankfully, laser engraving is very environmentally friendly. It uses no chemicals or consumable products to make the marking.

There are no residual leftovers after laser engraving and no additional treatment to the metal will be required. Unfortunately, this isn’t the case with many other methods that exist out there, which may leave residue or abrasions behind. Not having to worry about cleaning up or dealing with any residuals helps save companies time and money, as well.

Works on Nearly All Metals

No matter what kind of metal your manufacturing company needs to mark, there is a good chance laser engraving can help. Steel, aluminum, brass, nickel, copper and several other types of metal can be marked safely and effectively with laser engraving. Also, in many cases, it won’t matter if the metal is coated or bare, as the engraving will still work.

This will prevent you from having to use different marking techniques on different products, which could be expensive and time-consuming. Laser etching can add numbers, letters or any different type of character or symbol you need as well. A single word or character can be etched, as can an entire sentence or paragraph, depending on your needs.

Laser Etching Offers High-Quality Marks

Another benefit worth mentioning is the high-quality marks that are left with laser etching. Other marking methods can run or fade, which can make products or parts hard to identify later down the road. Laser etching will lead to long-term traceability, all without any extra time, money or efforts.

Laser etching on metals will experience far less wear and tear over time than almost any other method. Also, many other methods simply do not work on curved metals or surfaces, which limits how useful and effective they can be. The laser can also work at different depths, which offers a lot more control when deciding how to mark a material.

Whatever the type of product you are manufacturing, laser engraving can provide you with several advantages and benefits.

In closing, here’s a video from Duggan Manufacturing: