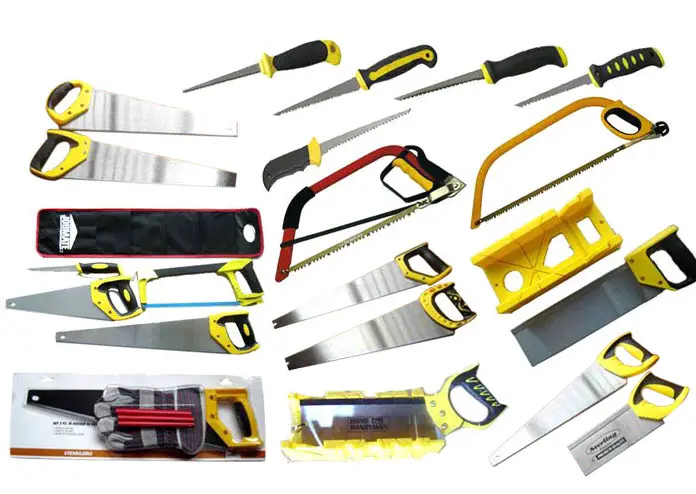

If you’re into woodworking and carpentry, you may know by now that the saw is something you cannot do without. It even gets your job done when you’re working with metal.

Not all saws are created equal but we’re not talking about the quality, but about their type. A specific saw may work for a specific job so you should do due diligence about the types of saw that are out there. Using the right type of saw can make the difference between a job well done and a completely failed one.

Without any further introduction, here are some of the most important types of saws that you can use for carpentry and woodworking. Choose wisely and don’t be afraid to try them as many as you can.

Page Table of Contents

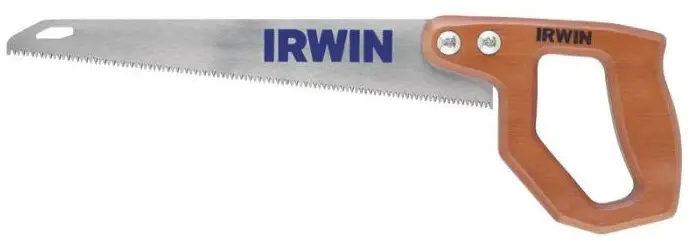

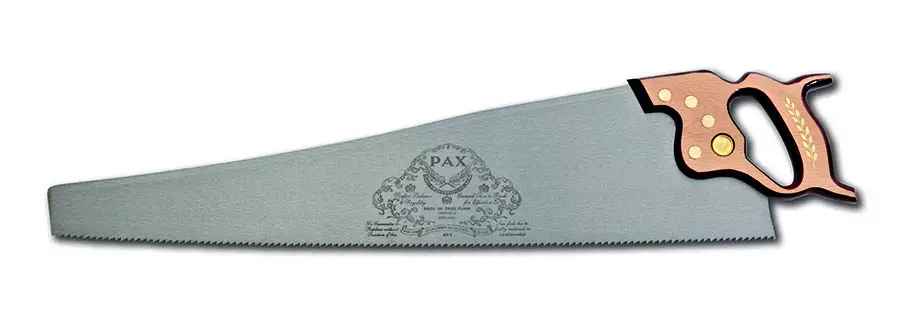

Traditional handsaw

This is probably the most common type of saw and the first to come to mind when thinking of a saw. It features a wedge shaped blade and presents a pistol grip handle. If you’re big on woodworking, this may be the very first type of saw that you should buy.

The Stanley 20-045 15-Inch Fat Max Hand Saw gives you speed and precision cuts as it’s made with SharpTooth technology (cuts 50% faster than regular saws). It comes with induction-hardened teeth that keep the sharpness for a long time.

The saw has an ergonomic design and excellent grip, with minor risk for slipping and great comfort throughout the use. You can use its back for marking 45 degrees and 90-degree angles, speeding up your measuring.

Even if some consider the blade a bit small, the saw is precise and easy to use, which seals the deal for many.

Designed for the accurate cutting, the WilFiks 16” Pro Hand Saw is a versatile handsaw that you can use on plastic pipe, wood, wallboard, or plywood. It’s a solid choice for the framers, woodworkers, and contractors.

The handsaw has a good built and features induction-hardened teeth that don’t lose sharpness that soon. It has an Anti-Slip Super Grip handle that is comfortable and doesn’t slip. It fits most hand sizes and reduces the risk of strain when cutting. Its design also provides a superior cutting angle. You should use the handsaw for the push and pull strokes, as the deep gullets ensure fast removal of chips.

Some may think that the handsaw doesn’t have a durability feel for it, but the high carbon steel blade and all the other good things sure make up for it.

Coping saw

This is another popular type of saw and it’s rather simple to look at. It consists of a thin blade and a D shaped frame, containing the blade. It’s a really helpful saw.

Coping saws may come with various types of blades so that you may cut both wood and metal. The best part about this type of saw is that you may remove its blade, put it into a hole (that you’ve already drilled) and cut the profile you need.

You are going to use the coping saw for cutting curves, moldings, joinings and even fashion dovetails. Even though this saw isn’t the most precise one, it’s still very helpful on various jobs.

The Olson Saw SF63510 Coping Saw Frame Delude Coping Frame is a professional option that helps for tensioning both ends on pin end coping blades. You can turn the edges 360 for sawing in whichever direction you need.

The handle is made of hardwood and has a durability feel to it. The saw comes with 15 TPI blade, and it’s well made. It could need better tension adjustment, but it delivers excellent performance nine times out of ten.

If you’re looking for a coping saw for small jobs, the BAHCO 301 6 1/2 Inch Coping Saw is a reliable option. The saw comes with nickel plated steel frame and a wooden beech handles (it’s orange lacquered, so it’s easy to spot).

The blades are interchangeable on retaining pins and are made of hardened and tempered carbon steel. It’s dependable, sharp, and the misalignment of the blade holder in some situations isn’t a deal breaker for most.

Japanese saw

Also known as “dozuki”, the Japanese saw is a common choice for the Japanese woodworking and carpentry. Unlike the western saws, this one cuts on the pull stroke. It seems that this type of cutting is more efficient and it also leads to a thinner cut width.

Japanese saws typically come with thinner blades than most of the saws out there. They present two kinds of teeth-crosscut teeth on one side (for making the guide path) and the rip teeth (for finishing the cut).

The downside for this type of saws is that they cannot cut hard wood (which most western saws are able to do just fine). They’re a better option for the soft wood (cypress or pine).

It’s quite common for the Japanese saws to come in a kit. Here are some examples:

- Azebiki- it has a short and curved blade which is good for starting center panel cuts

- Anahiki- works for general construction when cutting logs or beams

- Dozuki- it’s a back saw to use on joinery. It’s also known as dovetail dozuki.

- Kataba- you may use it for general purpose. It’s a single-edged saw that presents a thick blade.

- Kugihiki- it’s for flush cutting wooden nails and dowels

- Mawashibitiki-it has a narrow and thick blade that is great on curves and keyholes

- Ryoba- it’s the most popular Japanese saw. It looks a lot like a spatula and has crosscut teeth on one side and the rip teeth on the other

- Sokomawashibiki- it’s a curved saw that you may use for curved profile

A video from The Samurai Carpenter explaining these fine tools:

The best feature for the Gyokucho Razorsaw Ryoba Saw 180mm No. 291 is that you can tilt the handle according to with the blade. It’s a great feature that helps you get into impossible to reach areas. Boat builders, restoration workers, and carpenters find this saw extremely useful. The teeth are impulse hardened, which expands their durability.

Rattan is wrapping the handle, for better grip. The blades are easy to interchange, but some find it to be too easy (rending one to always screw the handle after every use). It’s a lightweight, and small saw that you could carry in a work bag or toolbox and use for precise cuts.

Helping you get a clean edge, smooth and accurate cuts, the SUIZAN Japanese Pull Saw Hand Saw 9-1/2″ Ryoba (Double Edge) is made for the high precision jobs. It’s made in Japan and impresses with the build and design.

The blade is sharp and thin, whereas the kerf is narrow. The inexperienced are going to find the saw challenging to control (the edge is short), but the saw is excellent to use when accuracy is fundamental for your job.

Crosscut saw

This type of saw is able to cut wood perpendicular, right to the grain of the wood. It’s the opposite of the rip saw (which helps you cut wood parallel to the grain). It cuts on the push stroke, just like the majority of Western saws.

It comes in a great variety of sizes. You’re going to use a small crosscut saw for the accurate woodworking and a larger model for the coarse woodwork.

The crosscut saw is one of the oldest models and there’s proof that even the ancient Romans used them.

Standing out with the aggressive tooth pattern, the GreatNeck N2610 – 26 Inch 10 TPI Cross Cut Hand Saw is an excellent choice to have around your sharp. Even if the price may be the selling point for many, the cross-cut saw brings a lot more than that to the table. It features a high carbon steel blade that is easy to resharpen when needed.

The handle is made with dark stained hardwood, and it’s weather resistant. The grip is secure, and the cross-cut saw is easy to use. The blade is accurate, and even the set on a tooth is too much for some, the precision and reliability are going to make you forget about that.

Made in the USA, the Metal Crosscut Saw with 28-Inch Blade for Wood. Lumber has a 28in blade with 4TPI that performs well on both dry and green round logs. It’s a heavy duty saw that doesn’t clog bind up.

You can use it for logs up to 12 in in diameter. It cuts a subtle wide kerf and is sharp out of the box. It has a sturdy build and rocks well, but you shouldn’t count on it for the precision jobs.

Back saw

This is just another hand saw, but it sure stands out from the crow with the stiffening rib on its upper side. The stiffening edge doesn’t let the blade bend when you’re pushing. This is why the backsaw is going to cut a lot more precisely than many other types of saws. It also provides better control to the user.

You are going to want to use the backsaw for the accurate cuts in cabinetry and joinery. The most important asset comes with a big downside: you’re not going to be able to cut as deeply, but you’re going to solve it with another type of saws. After all, there are so many to choose from.

Designed for the accurate cutting, the Stanley FatMax 17-202 14-Inch Back Saw is both affordable and dependable. Its build is durable, and the saw comes with strong screws that keep the blade in place.

The handle is made with one piece bi-material for a longer lifespan and increased comfort throughout the use. You should use it for the plywood, hardwoods, and beautiful finish. The saw has a right balance, and even some may find it tricky to use, it’s a valuable option to have around your shop.

The price may throw some off in the case of Crown 195 12-Inch Tenon Saw with Full Handle, but the saw is worth every single penny.

The amazing quality of the saw is its main upside, and the saw comes with a carbon steel blade that you can resharpen when required. The stained beech handle is secured with screws and has a comfortable grip. It impresses with the finish, whereas the Brass back has a nice weight to it. it’s a 13 TPI saw that is tight, rigid, and solid- but only in a good way. Some may find it difficult to begin the cutting, but the saw cuts fast and clean when used right.

Keyhole saw

This saw sure looks a lot like a swordfish or the sword per se. you may know it as the “drywall saw/ alligator saw/jab saw or pad saw. Even though it’s a narrow kind of saw, it’s also quite versatile.

You may use it to cut curves, circles and frets, especially in places where no other type of hacksaw is able to do a good job.

Lightweight, the keyhole saw presents and pistol grip which ensures easy use. There are 2 types of keyhole saws: the one with retractable blade and the one with fixed blade. Be ready to pay the extra buck for the retractable blade keyhole saws.

The Stanley 15-556 Jab Saw with Cushion Grip is quite a nice surprise for the money. The saw comes with a fully hardened and tempered blade that handles use for quite some time. The tip is sharp, so the plunge cuts go easy. the teeth are designed for fast cuts and present low risk for clogging.

The handle has an ergonomic design (it’s curved) and it’s also cushioned for increased comfort. The blade is epoxy-bonded to the handle, which explains the durability of the saw. Some think that the handle gets slippery at times, but the saw is great for the straight lines and even curves, so why not giving it a try?

The built-in blade and the handle design give the Greenlee 301A Key Hole Saw Ergonomic Handle, 6″ amazing strength. Even if the pointed butt is a downside, the saw has an ergonomic handle and a non-slip grip.

The steel blade is hardened and comes with teeth that don’t want clod, whereas the pointed tip is going to go nice and easy through the drywall. You may use it to push and pull strokes, and the saw stays sharp for a reasonable amount of time.

Compass saw

The name of this type of saw is a bit confusing. When it comes to carpentry, woodworking and architecture, the word “compass” relates to a curve. Therefore, the compass saw is the main kind to use for cutting curves.

The compass saw is narrow and comes with a tapered blade. The blade is pointed at the end most of the time. The common type of compass saw comes with 8-10 teeth per inch, but this may go up to 20teeth per inch (in case you’re going to cut some harder materials).

This type of saw also presents a pistol grip which is going to help you work easier in confined places. Its pointed end is going to penetrate nice and easy the soft materials, eliminating the need for a pilot hole.

The Stanley FatMax 17-205 12-Inch Compass Saw is made with tough screws, securing the blade for long time use. It’s a solid and one piece bi-material handle on the saw that is both comfortable and long lasting.

The steel blade is sharp and strong, and you can use the saw for accurate cutting and interior curves. The saw has a tough build and stays sharp for a long time, which counts considering that the blade isn’t replaceable.

The Shark 10-2207 Compass Saw comes with an 8” blade that helps you cut curves in most materials, drywall, plywood and paneling including. It has 11 TPI and an easy-to-use handle. The chisel point blade is beneficial for the plunge cutting. You may use it for framing, thick, rough, and odd cuts, but it may not impress on the fine cuts.

Fretsaw

When you’re trying to make some intricate cuts in wood, a fret saw is going to be the best choice. It also goes without saying that this one is great for the really tight curves too.

The coping saw is in fact a type of fret saw, but the last one is going to be able to make cuts with a tighter radius, helping you perform the most delicate cuts.

The fretsaw is a deep frame saw (10-12inches) and features a short 5inches blade. The blades can get up to 32 teeth every inch, which helps you make the tighter cuts.

The main pet peeve? The amazing ability of the saw comes with a price and the fret saw sits on the fragile side, so you want to be extra-careful with its blade.

The Knew Concepts 5″ Woodworker Fret Saw features a 15TP no.7 skip-tooth blade. It’s easy to adjust and to maneuver saw, that feels lightweight and comfortable in any hand. Even if it’s lightweight, the fretsaw insanely strong and tough. It has just on blade holder, so changing the blade and tensioning are easy to operate.

The frame is stiff, and the blade doesn’t break that easy. It’s dependable for large fretwork and removing waste from the hand-cut dovetails. It’s an impressive and long-lasting saw; even some consider it’s a bit wobbly on a side.

Even if it doesn’t come with a blade, the Olson Saw SF63507 Fret Saw still makes it as a dependable option when you go shopping on a tight budget.

The saw is good for the deep cuts and the light work in your shop. Its handle is easy to fold between the frame ends when you store it away. You can use it with 5” fret, jewelers, scroll, and spiral saw blades.

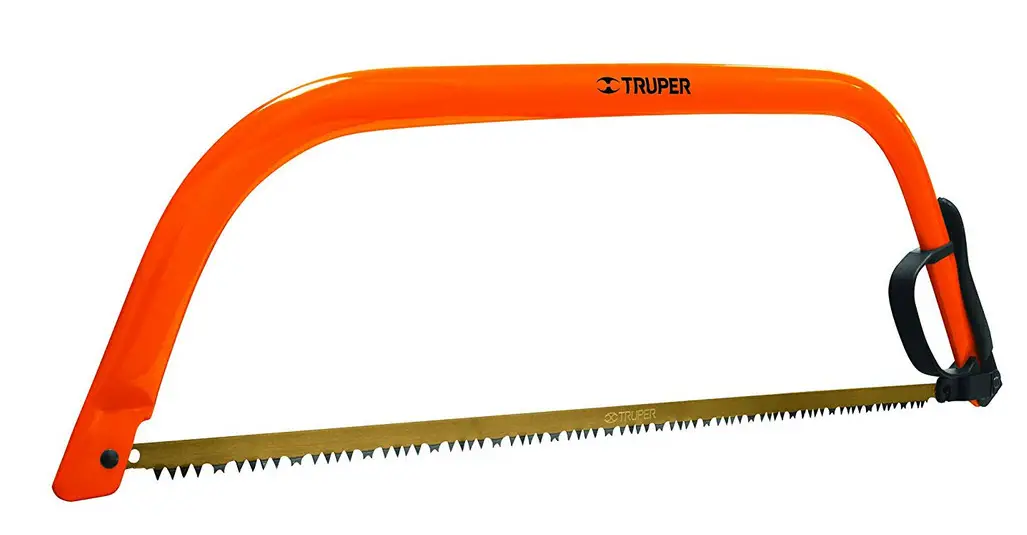

Bow saw

Its name says it all and the bow saw does look a lot like a bow. Some call it the buck saw/ finn saw or swede saw.

No matter the name, the bow saw presents a coarse wide blade and works for cutting wood (firewood is easy to cut with this one). This saw is definitely the no.1 choice when cutting some green or wet wood.

The bow saw is a lot like the frame saw as the blade is maintained in tension inside the metal frame. Many gardeners are using the bow saw as it’s very easy to use for pruning or cutting branches of trees (up to 6 inches thick). You may use it for both straight and curved cuts.

Made for the harsh environments on construction sites and challenging applications, the Bahco 10-24-23 Bow Saw with Ergo Handle presents an effective tensioning mechanism for the straight cutting and high blade tension. The ergo handle features a knuckle protector for increased safety and comfort.

It’s lightweight but tough and dependable for the quick release changes and accurate tensioning. It comes with hard point peg toothing, and it’s affordable.You may replace the blade, but you should pay attention as the risk for over-tightening is important.

For those of you looking for a bow saw for the large branches, the Truper 30255 Steel Handle Bow Saw, 21-Inch Blade is one great choice to consider. The cam-lever tension system is going to maintain the blade tight throughout the work. The saw is well made, and it’s dependable when cutting logs. It doesn’t come with a foldable frame, but that’s a minor issue considering its overall value.

Veneer saw

This small saw is a solid option when cutting hardwood veneer. The blade is no longer than 4 inches and it features 13teeth per inch.

The most important feature of the veneer saw is that you may practically cut with both the edges. It’s the ideal type of saw when you’re planning some veneering work.

On a side note, veneer is the thin covering made of some fine wood (3mm at most) that is going to be applied on a coarser wood, leading to a flat panel. Veneer wood is really thin, but it’s still wood so a knife isn’t going to be of any good. A veneer saw is always going to be the better choice for cutting the veneer.

The overall quality of the Crown 187V Veneer Saw is going to impress most users. The saw is great for pull and push strokes and comes with a high carbon steel blade.

The minor issue is that you need to sharpen it before the use and every time it’s needed. It’s a 15TPI saw that has a well-attached beech handle. The teeth cut on both sides, and the saw has a professional look and build.

When you want to cut a perfect edge for joining veneer, you should rely on the Two Cherries 520-2200 Veneer Cutter. The veneer cutter is easy to use, and it’s made for the pull stroke.

Its curved blade helps you begin in the middle of the material. The attention to detail is impressive, and even some expected more for the longer cuts, the saw is well made and useful in a shop.

Band saw

This is one of the many kinds of electric saws that are on the market nowadays. The cutting edge is made of a serrated steel belt that is moving constantly.

The band saw is a woodworking saw, but it does a good job in lumbering, metal working and even on cutting metal.

As the tooth load is evenly distributed, the band saw ensures uniform cutting and helps you cut irregular and curved shapes too.

It’s important to highlight that this saw is really dangerous so it should be used only by the experienced ones. Don’t forget to be careful of kickbacks as well.

Easy to put together and great value for the money, the WEN 3962 Two-Speed Band Saw with Stand and Worklight features a 3.5amp motor which ensures up to 6in deep and 9-3/4in wide. It has 72-in blades from 1/8 to 1/2in in size.

It can operate on two speeds (1520 or 2620RPM) and has an adjustable fence, beveling table, sliding miter gauge and 25in stand. It has a ball-bearing operation and flexible work light with a power switch. Even if adjustments are a bit tricky to reach, the band saw is always a wise investment of your money.

Presenting an all bearing build and featuring a cast iron frame, the Grizzly G0555LX Deluxe Bandsaw, 14″ comes with computer balanced cast iron wheels and rubber tires.

The upper and lower ball bearing blade guides and thrust bearings. The band saw comes with the miter gauge, extruded aluminum fence, and blade. It’s well made, and you can easily overcome the rather shallow dust collection port.

Rip saw

The tip saw is going to cut wood parallel to the grain, which is different from a crosscut saw that does it perpendicular to the grain. It looks a lot like the crosscut saw, but there’s something different to notice right from the first glance. The teeth on a rip saw are in fact angled backward about 8 degrees or so. In the case of cross cut saw, it’s 15 degrees for the angle.

You can use the rip saw just like a chisel, as it eliminates anything it runs up against. It works like a knife, cutting the fibers from the wood.

Most rip saws out there come with 5teeth per inch, whereas a cross cut saw is going to have twice the number.

First thing you’re going to notice on the Lynx Garlick Thomas Flinn British 20” Rip Saw with Taper Ground Blade is the handle. It’s beautifully polished and ensures a good grip.

It’s stained European Beech that comes with brass button screws. The saw is hand sharpened and cuts very well. the plate allows spring steel and taper ground. The 20″ blade has 4.5TPI, and it’s made for rip cutting.

Even if the nice fit and finish make a great first impression, the Crown 190 24-Inch Rip Saw with 4.5 TPI is more than meets the eye. The taper ground is made with nickel chrome alloy steel, whereas the stained beech handle is secured with screws.

The teeth are sharpened and set, and the saw has 4.5TPI. some think that it could use a smaller handle, the saw works very well, and it’s aggressive on the rip.

Jig saw

The jigsaw is a reciprocating saw that you may use for cutting various shapes in plywood. It’s also known as the bayonet saw or the sabre saw. The biggest challenge when using it is the control as the blades are rather weak and small. There’s also no support at the lower end.

If you’re planning to make a curved cut with the jigsaw, you should steer the blade without forcing it sideways. If you’re going to force the blade, you may obtain an uneven cut or even break the blade.

You may find various types of blades that work for the jigsaw, increasing its versatility.

For those of you who go shopping on a tight budget, the BLACK+DECKER BDEJS600C Smart Select Jig Sawis probably one of your best shots. The jigsaw is made with Curve Control technology so that you may adjust the orbit in 1 of the fours customized settings.

The jigsaw features a 5Amp variable-speed motor which delivers up to 3,000 SPM of cutting power. You can use it when making your 45-degree bevel cuts. The saw could perform better in terms of precision, but it’s strong and loaded with features that turn it into a bang for your buck.

Strong without causing vibration, the Bosch JS260 120-Volt Top-Handle Jigsaw comes with four orbital-action settings. It has adjustable speed (use the dial for the maximum speed) and adjustable dust blower so that the cutting line is always clean.

The jigsaw features a heavy gauge steel foot place and on-board bevel wrench storage. Some find the base difficult to stand straight, but that’s a minor flaw when you take a look at all the other good things.

Track saw

Many are mistaken the track saw and think it’s a circular saw. However, the track saw (rail saw/plunge saw) is used for cutting sheet material. This doesn’t mean you cannot use it for cutting wood and other materials.

Keep in mind that getting a straight cut with the track saw is going to be really difficult. You may have a win only if the piece of wood is clamped down.

Most track saws out there are going to come with an aluminum guide which is going to help you make the sharp cuts.

Not only that the WEN 36055 9-Amp Plunge Cut Circular Track Saw with 2 Guide Rails is reliable for all sorts of jobs, but it’s also an affordable model too. The track saw can create 45-degree bevel cuts, and it’s great for ripping boards or the internal plunge cuts. The self-retracting riving knife reduces the risk for kickback and pinching. It may not be the sharpest blade for the saw, but it comes with many features that give it a good value for the money.

Even if the Festool TS 55 REQ Track Saw may look pricey to many, the track saw is impressive within its accuracy, performance, and overall build. The spring-loaded riving knife is going to maintain the cut kerf open, which is why the blade doesn’t pinch the blade. The risk for a kickback is minor, and the cuts are straight and accurate.

It’s easy to change the blade, and the FastFix systems keep you on the safe side at all time. It doesn’t come with clamps, and it’s albeit expensive, but it’s a great investment to make in the long run.

Scroll saw

If you’re going to take a look at a scroll saw from a distance, you may think it’s a sewing machine. Truth be told, it’s a pedal operated saw.

The scroll saw is a good option when planning to make an intricate curved cut. This one combines the functions of a jigsaw and a coping one just fine. You may see it as a type of band saw. Unlike the band saw which uses a steel band that loops continuously, the scroll saw is based on a reciprocating blade.

You may remove the blade on the scroll saw and place it into a drilled hole. This is going to let you make interiors cuts without needing an entry point.

The WEN 3921 16-inch Two-Direction Variable Speed Scroll Saw comes with a one-of-a-kind design as it takes blades in two directions (standard and 90 degrees), which counts for infinite ripping ability. The speed is adjustable from 400 to 1600 SPM, and the saw cuts wood up to 2in thick.

It comes with a thumb screw blade adapter for easier blade changing, an air pump, a dust port, a cast iron base, three blades, -on-board storage, and a foot lock clamp. It’s a solid option for a beginner, but it may not satisfy the more experienced carpenter.

When you’re ready to step up your game, take the leap of faith with the DEWALT DW788 1.3 Amp 20-Inch Variable-Speed Scroll Saw. The double parallel-link arm design is reducing vibration and noise, giving highly accurate cuts. The tool-free blade clamps help you change the blade instantly.

The saw has an adjustable speed, blade-tensioning lever on the front upper arm, flexible dust blower, and on/off switch. You may lift the arm so that the blade threads through the material. Impressive and dependable, the scroll saw is heavy, but it’s a small downside considering its value.

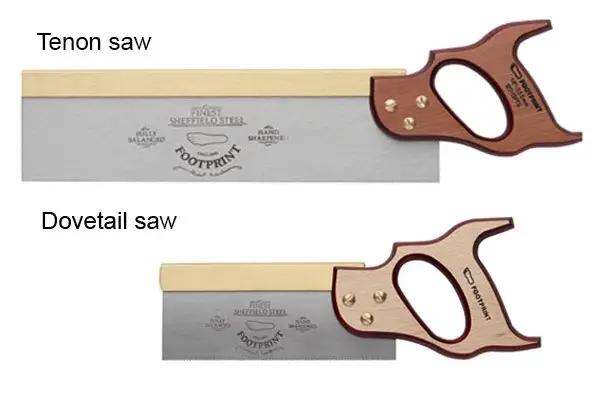

Dovetail saw

This saw comes with 15-20 TPI (teeth per inch) and you may use it for dovetail joinery. It’s a great saw to use for applications that need a small, yet very accurate cuts. When you’re looking for an impressively neat finish, this is the saw to use. It works on both hardwood and softwoods.

The Two Cherries 520-6020 10-Inch Brass Back Dovetail Saw is a valid option to use for cutting dovetail and various fine joints. It comes pre-sharpened and has 15 TPI.

It features a high-quality German steel blade, and the handle has the perfect size for easy and strain-free use. Some consider there’s a little grab for the teeth, but the craftsmanship and reliable performance turn it into a solid option for many.

For the customers that value the extraordinary craftsmanship on their tools, the Rob Cosman’s Dovetail Saw, Black Resin is a mandatory addition to their professional-grade collection.

The say is handcrafted and personally tested by Rob Cosman, coming in a storage case. The first two inches of the blade present 22TPI for an easy start, whereas the remaining of the edge includes more aggressive 15 TPI for finishing the cut friendly and comfortable. The Brass back is heavy, but the saw ensures smooth cuts, with no risk for vibration. The price is the pet peeve for this one, but you should focus on the accuracy and incredible performance when buying.

Carcass saw

you should use it for accurate cuts across the grain, defining edges of a dado or cutting Tenon shoulders. It comes with 14 points per inch and ensures fast, smooth and precise cuts. It’s a great saw that complements the dovetail saw.

Circular saw

You’re going to use the circular saw for cutting metal, wood or concrete. It’s made with an abrasive/toothed disc on an arbor, using a rotary motion for making the cuts. You may find handheld models and various mounting options too.

As for the blades, they’re also different as you need to use specific ones for specific materials. You’re going to need to use different blades for making rip cuts, cross cuts or a combination of the two.

The main downside when using the circular saw is the limited depth of the cut. You unlock the shoe (you can use the lever for it) by adjusting the height of the blade and moving the shoe upwards. Lock the blade once again afterwards.

The 14amp motor provides 5,300RPM for the SKIL 5280-01 15-Amp 7-1/4-Inch Circular Saw with Single Beam Laser Guide; therefore you can use the saw for fast cuts and great speed. The circular saw comes with 7-1/4in carbide-tipped blade and a spindle lock for straightforward blade change.

It’s lightweight and strong and comes with a dust blower. The anti-snag lower guard reduces the risk of snags. The handle for controlling the depth may fail the durability test, which doesn’t compromise the overall value of the circular saw.

The Milwaukee 2730-20 M18 Fuel 6 1/2″ Circular Saw comes with a brushless motor and advanced electronic system for maximum performance. It’s durable and strong, yet lightweight. The risk for overheating and over-discharging is minor, and the Li-Io circular saw features cast magnesium guards and show.

It also comes with LED light and a rafter hook for easier storage. Some find it tricky to use the safety interlock, but it doesn’t count much when buying.

French flush-cut saw

This saw comes with teeth angled a bit upward so that it doesn’t damage the surface while cutting. It’s a double-edge saw that comes with 2 different TPI- 11 on one edge and 20 on the other, most of the time.

The Robert Larson 720-3000 Flush Cutting Saw has a flexible and thin blade, which makes it a reliable option for cutting pegs and dowels.

The wooden handle is going to need some sanding, but the saw is great to have. It’s not going to mar the surface area and gives clean cuts every time.

The flexible blade of the DEWALT DWHT20541 Flush Cut Pull Saw recommends it for the perfect flush cuts. The saw cuts fast and clean on the pull stroke, so you may have to be careful and not to push (you’re going to bend the blade if so).

The blade is sharp, and the grip is good, whereas the double-sided blade allows easy cutting to the left/right. It may not be the perfect tool to work on angles, but the saw is a great choice for trimming through tenons or some lap joints.

Miter saw

This is a multi-function electric saw that you may use for making cross cuts (perpendicular to the grain of the wood), bevel cuts (this is an angle cut and you need to cut across the thickness of the board), miter cuts (it’s an angled cut that goes across the width of the wood) and compound cuts (it’s a combination of the bevel and miter cut). You need to adjust the miter saw for making each of this type of cuts.

You can use the miter saw for making wooden frames and molding and it ensures high precision for each of the operation. However, you’re not going to be able to make rip cuts with the miter saw.

The DEWALT DW713 10 in. Portable Compound Miter Saw features a 15 AMP motor that gives 5,000RPM, rending the miter saw to be both strong and long-lasting. The stainless steel detent plate features 11 positive stops for better accuracy, whereas the sliding fences sustain the crown molding vertically.

It’s easy to slide them out for the bevel cuts. The machined base fence keeps the fence perpendicular with the blade for improved precision. The miter saw comes with a lock for fast and precise table positioning. It may be off by a degree when out of the box, but that’s easy to fix.

The 12.in blade of the Delta 26-2250 12″ Dual Bevel Sliding Cruzer Miter Saw comes with a versatile flip-down fence design. The miter saw has an adjustable crown fence lock and seven positive stops at main bevel angles, for the front slope.

The right miter has ten miter detents and positive stops. The override lever is easy to reach for moving between stops. Strong, well-made, and not heavy, the miter saw is money well spent, even if the dust control could use some improvement.

Razor saw

This one is the perfect small saw that you may use for the small projects or model making. It’s made with 40teeth per inch and its blade provides a smooth finish to any project.

It works great for the fine cuts in soft wood and may come with disposable blades.

The Zona 35-550 Fine Razor Saw, 42 TPI.010-Inch Kerf is a versatile tool to have around your shop that you can use for woodworking and modeling.

You can confidently use it for cutting copper, wood, plastic or Brass as it leaves nice smooth edges every time. It’s an affordable knife that is good for the fine works and doesn’t mark your pieces. Its blade is fine and sharp. The handle could be better, but the saw looks rather well altogether.

When you need a saw for the excellent cutting for railroad tracks or model parts, the Xacto X75350 Extra Fine Razor Saw Set is a solid option to keep in mind. You can use it for cutting metal parts, wood, and plastic.

The handle is made with tough plastic, but the blade is thin and sharp. The handle ensures comfortable use and looks quite nice. Some find it tricky to assemble the saw, but it’s worth to spend a couple of minutes, considering the overall value and the bargain price.

This is a blade on an arbor, set in a table. The blade is coming up from under the table, as the table is going to support the material that you’re cutting.

This is dangerous saw as the blade is exposed to you, so you need to be extra-careful when using it. Exposing more or less of the blade is going to help you adjust the depth of the cut. The more the blade is going to protrude, the deeper is going to be the cut.

The modern models come with a high number of safety features for keeping you safe. Magnetic feather boards, dust extractors are only some to mention. You may reduce the risk for injury by lowering the blade height.

One final thought

Even though we presented the basics of some types of saws, we didn’t cover them all. The variety of saws is impressive and you should look the ones you need for the most special jobs. Do due diligence and don’t take a stab in the dark when using one. Never.