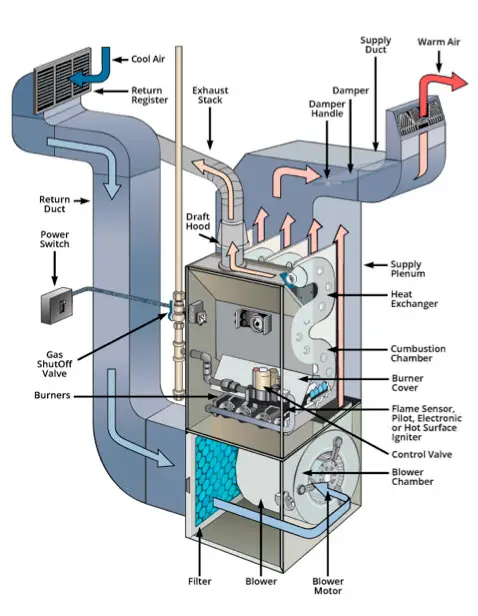

Your gas furnace uses propane or natural gas for fueling, and older models come with exhaust running throughout the house and then straight through the roof. As the chimney isn’t exactly easy to reach, most homeowners have no idea how hot it can get. The plan for combustion air and flue gas vent systems are always important, no matter if your household comes with a standard furnace (50-70%), mid-efficiency (70-80%), or a high-efficiency model (anything about 90%).

Page Table of Contents

What does AFUE refer to? Should you consider it on your furnace?

The quantity of fuel that the furnace transforms into heat gives the AFUE (Annual fuel utilization efficiency) rate on your furnace. It’s common for new and higher-efficiency furnaces to impress with AFUE over 90%. It means that 90% of the fuel will be transformed into heat, whereas the rest of 10% will be lost throughout exhaust.

To make an idea, older models would present an AFUE rating from 50-70%, so the 90% rate is impressive. Moreover, a higher AFUE rating means lower utility bills for you as more propane/natural gas is turned into usable heat.

Are the vents on new models different from the traditional ones?

For a better understanding of the exhausting vent of high-efficiency models vs. Lower efficiency models, we have to take a closer look at the heating process. Every heating process will generate waste materials or byproducts, and furnaces hot water vapor is the byproduct. It makes perfect sense not to want the byproducts around the house, so a system for collecting and eliminating the hot vapors is necessary.

The exhaust gasses go through a vent system in the chimney or roof for traditional furnaces, but an actual amount of heat gets lost while the water vapor is vented through your chimney outside the house.

As using all the heat generated throughout the combustion process is crucial for the performance of the furnace, high-efficiency models will utilize two heat exchanger heater and not just one like all the other models. The second heat exchanger will collect heat from the water vapor throughout a cooling process that becomes condensed, turning into liquid. When the liquid remains in the pipes, the acidic condensation will affect the pipework, causing hazards for your safety and health.

Therefore, the high-efficiency furnaces are vented with PVC pipes that are made to handle the acidic condensation. Some lines will exhaust the outside, whereas others will seep the liquid condensate straight into a floor drain. Older models would come with metal pipes, but high-efficiency furnaces come with PVC pipes as the flue gases have a lower temperature. It’s not regular plastic, though, but a specially rated plastic resists the acidic condensation.

Some exhaust pipes must always be vented to the outdoors, so you should never vent them through your chimney. When the exhaust pipes are placed outside the home and not inside the chimney, they’re easier to observe. Even if it looks like you’re losing heat and energy through the exhaust, you shouldn’t worry at all.

Should you worry about icicles around the exhaust pipes?

If you live in a colder area, there’s a good chance for icicles to form around the plastic exhaust pipe. It’s the high humidity exhaust that freezes throughout exhausting. Most of the moisture will go back to the furnace, where it’s seeped into a drain. It’s also the reason for which the PVC pipes on high-efficiency furnaces are sloped ¼” per foot back towards the unit, sustaining the draining process.

You may reduce the risk of icicles if they become a problem. Most of the time, the pipes are easy to reach and feel quite warm.

Should the pipes be hot or not?

As the fans are running, you may check the pipes’ exterior and see that it feels quite warm. It’s the little lost heat from your high-efficiency furnace, and you shouldn’t worry about it. It’s the main reason for which you paid the extra buck for the high-efficiency model, anyway.

However, if the temperature is relatively high, several aspects could cause the problem. Dirty filters, blockage in the chimney, something stuck in the ducts, or lower blower speed is possible causes.

When the pipe is incredibly hot and cannot even touch it, you should call the HVAC technician for further investigation.

How hot is too hot?

The temperature testing for your high-efficiency furnace is made to ensure that the materials are within the secure working range of equipment. The tests are run for worst-case scenarios, which are as follows:

- The maximum temperature rise situation

- The furnace is mounted in a closet.

- At the maximum outlet temperature

- The unit is running at the high limit.

When the furnace is running at the mentioned conditions, the median vent material temperature cannot go over 167f degrees. The median temperature refers to the average of the material’s measured outer surface and the measured gas temperature. Should the measured exterior surface temperature on the vent pipe be 100f degrees and the combustion gas temperature is 140f degrees, the median material temperature should be 120f degrees for the safe operation of the vent material.

How can you measure the temperature in the vent?

100 to 130f degrees is the regular combustion gas temperature for a 90% AFUE furnaces. If it goes over 130f degrees, you may deal with a problem.

Here’s how to take the temperature correctly:

- Take the temperature inside the vent pipe, 8 to 12 outside the furnace cabinet.

- Create a tiny hole in the vent material, inserting the thermometer right in the middle of the pipe.

- Find out what temperature does the combustion gas inside the pipe presents

- Use some RTV silicone caulk or stainless steel screw for sealing the hole.

Can you use the temperature for diagnosis of your furnace?

Let’s say that the inducer keeps on failing. The drains are clear, the voltage is correct, and you see no signs of water collecting into the inducer and leading to failure. You check the vent temperature and discover that it’s over 150f degrees. It could mean that the induce is overheating, leading to failures.

Here’s what you can do:

- Please take a look at the manifold pressure so that it’s within range of the rating plate of the furnace (it’s 10.0 IWC for propane and 3.5 IWC for natural gas)

- Observe the temperature rise over the heat exchanger and check if the maximum discharge air temp is within the rating plate range.

- Please take a look at the blower wheel; it should be clean. If it’s dirty or worn out, you have to remove the blower assembly and clean the blower wheel and secondary coil.

- Don’t forget to also observe the static pressure. You have to add the negative pressure from the blower compartment to the unit’s discharge pressure before the coil. 0.5″ W. C. is the maximum external static pressure for residential models.

- Due to high gas BTU, the furnace could over the fire and cause the temperature to rise.

Before you go away

Never skip measuring the vent temperature on your high-efficiency furnace as it can help discover any problems inside your furnace. Even if high-efficiency models are performant, they still develop issues.